Air conditioner radiator recycling machine is a complete production line for recycling waste radiators to get metal copper, aluminum and iron. This production line can recycle scrap household AC radiator and waste car tank in good shape or in damaged form. Also it can recycle large radiators in many layers which are mostly used for cold storage and industry.

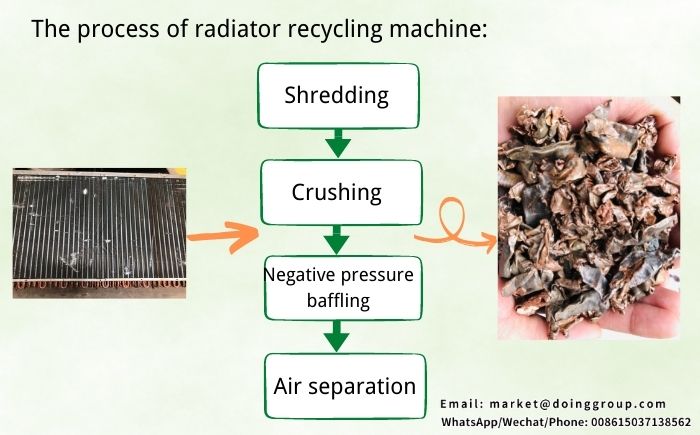

The whole process for air conditioner radiator recycling machine includes shredding, crushing, magnetic separation and air separation. After processing, the separated copper, aluminum and iron are very pure.

The first step is input scrap radiator into shredder to shred radiators into small pieces. We use a double shaft shredder which has a big torque can shred a large radiator but has low noise. The blades for shredder use alloy and are made by special technology which has a long service life.

The second step is crushing small pieces shredded by shredder to particle which size is less than 3cm, then copper, aluminum, iron are not composite but still mixed together. The crusher we used is hammer crusher, it has a strong crushing force.

The third step, mixed copper, aluminum, iron particles are transferred to negative pressure baffling system. This system can output lots of light aluminum and make the rest particle go to the next step evenly. This system can improve the efficiency of the whole process.

The fourth step, magnetic separator separate iron from mixed particles. The magnetic separator we used has strong magnetic force and it can remove iron automatically.

After the above steps, we use air separator to separate heavy aluminum and copper. Due to the different densities of copper and aluminum, under the action of wind force, the copper-aluminum mixture makes amplitude movement on a certain angle of the sieve surface. Because the density of copper is high, the resulting deflection causes the copper advance towards the outlet, the aluminum particles float on the copper particles and flow to the aluminum outlet, so as to achieve the purpose of separating copper and aluminum.The copper, aluminum, iron separated by this production line can be sold on the market directly.