Prefabricated Steel Structure Garage

1. GARAGE

When it comes to building your own garage, do not settle for just a few years after the deterioration of rickety wooden structures or leave you constantly leaking. Prefabricated Steel Structure Garage is custom designed according the detail size (Length ,Wide and Height ) , and still accommodates local wind and snow load. It will meet or exceed industry standards and regional requirements.Shengbang Steel Structure Co., Ltd. produce the most durable and reliable prefabricated steel garage provides secure storage for your car, tools and landscaping equipment. Our building is very affordable, because they are designed to do its own builders, and is equipped with an easy to follow instructions and drawings completely prefabricated garage kit.

Link Length

2. product details

|

Product Name |

Prefabricated Steel Structure Warehouse |

|

|

Specification |

Foundation |

Concrete and Steel |

|

Support |

X or V types, angle steel or round tube |

|

|

Surface |

Two layers and anti-rust paint |

|

|

Color |

White, Grey, Blue, Green, etc |

|

|

size |

Designed by your requirement |

|

|

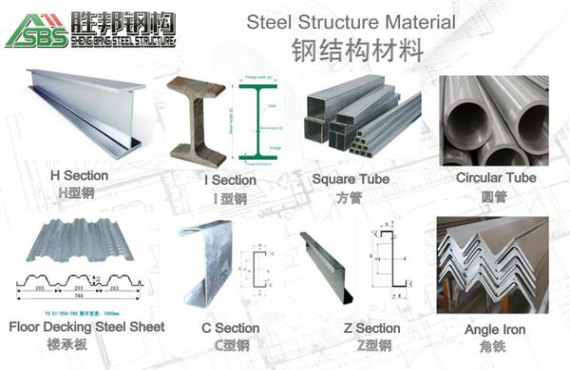

Main component |

Base materials |

Cement and steel foundation bolts |

|

Main frame |

H beam (welded or hot rolled) |

|

|

Material |

Q35B,Q345B |

|

|

Purlin |

C purlin (C120-320) or Z Purlin (Z100-200) |

|

|

Bracing |

Tie bar, lateral bracing, column bracing, knee bracing, etc |

|

|

Bolt |

Normal bolt, high strength bolts, Galvanized bolt |

|

|

Roof & wall |

Sandwich panel, steel corrugated sheet |

|

|

Door |

Sliding door , rolling shutter |

|

|

Window |

PVC window, aluminum-alloy Window |

|

|

Accessories |

Skylight, ventilation, downpipe and galvanized gutter etc. |

|

3. Description of steel structure building

1)Certification:SGS Standard,GHD Standard,ISO9001:2000

2)Steel structure design common norms are as follows:

"Cold-formed steel structure technical specifications" (GB50018-2002)

"Construction Quality Acceptance of Steel" (GB50205-2001)

"Technical Specification for welded steel structure" (JGJ81-2002, J218-2002)

"Technical Specification for Steel Structures of Tall Buildings" (JGJ99-98)

3)Commonly used steel grades and performance of steel

Carbon structural steel: Q195, Q215, Q235, Q255, Q275, etc.

High-strength low-alloy structural steel

Quality carbon structural steel and alloy structural steel

Special purpose steel

4) Wall & roof can be used by steel sheet, EPS sandwich panel, rock wool sandwich panel & PU sandwich panel.

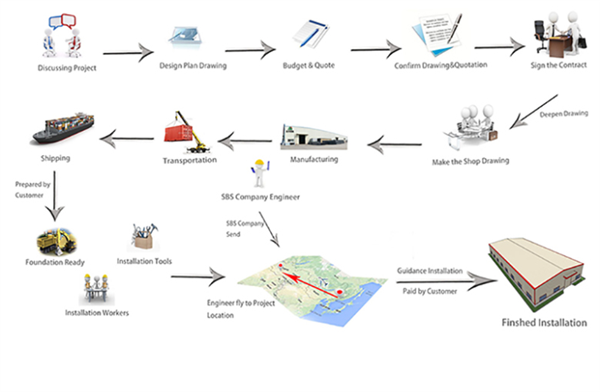

4. Service flow path

Discussing Project——Design Plan Drawing——Budget & Quote——Confirm Drawing&Quotation——Sign the Contract——Make the shop Drawing——Manufacturing——Transportation——Shipping——Foundation Ready——Guidance Installation——Finshed Installation

Demand Critical Welds