The bagging baling machine uses a hydraulic cylinder to compress the material in the compression chamber multiple times in various directions before pushing it into the bag. The bagging baling machine is mainly used for materials that cannot be baled or for materials that have specific storage requirements. The packed material blocks form a standard rectangular shape, which is both aesthetically pleasing and convenient for stacking and boxing, and will not spill during transportation. If PE plastic bags are used in conjunction with vacuum packaging, it can effectively prevent the material from getting damp and moldy during transportation and storage. When used in conjunction with a weighing conveyor, it can accurately control the weight of each bag, and when combined with a chipper, a screener, etc., it can form a complete production and packing line for wood chips.

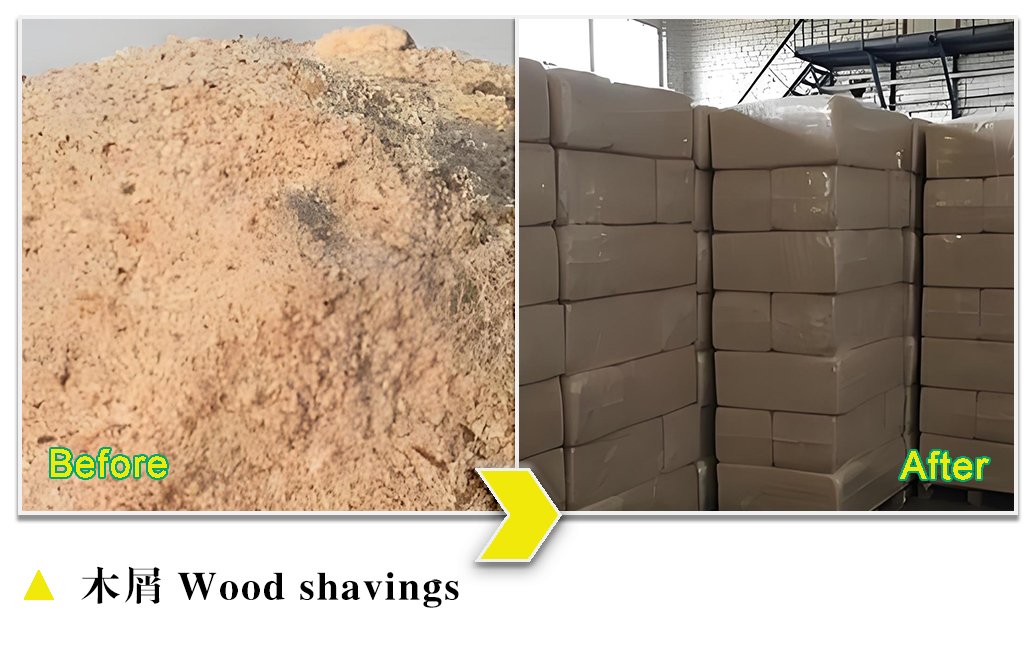

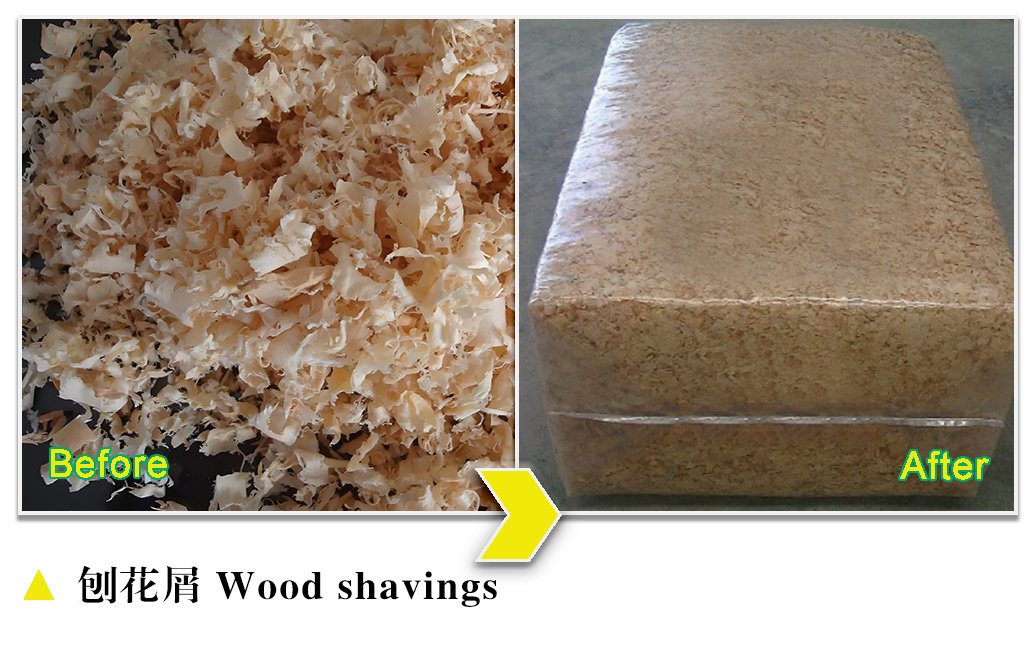

| Wood | Wood shavings, sawdust, etc. |

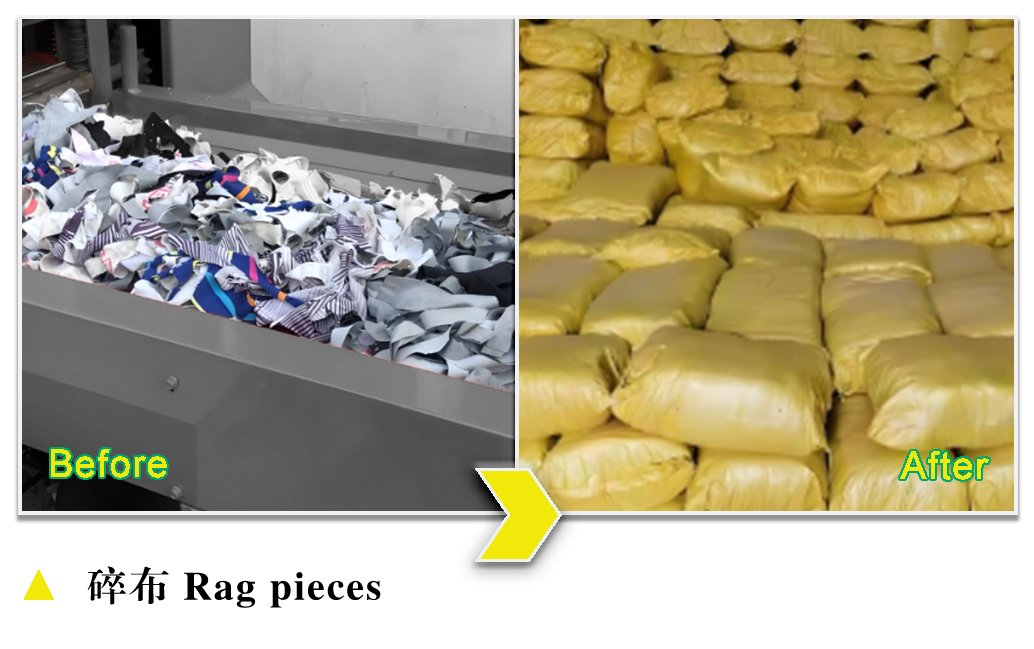

| Fabric and Leather | Clothing, rags, factory offcuts, textile scraps, leather scraps, etc. |

| Plants | Rice husks, alfalfa, silage feed, cottonseed hulls, etc. |

| Paper | Shredded currency, paper scraps, etc. |

| Soil | Peat soil, coir soil, etc. |

| Others | Rubber granules, sponge, foam, latex, etc. |

| Model | GBB-H2515 | GBB-H3323 | GBB-H4030 | GBB-H5050 |

| Packaging size (W×H×h)(mm) | 250×150×(600-800) | 330×230×(350-600) | 400×300×(450-600) | 500×500×(550-800) |

| Main cylinder pressure (T) | 10 | 20 | 31.5 | 63 |

| Sub-cylinder pressure (T) | 10 | 16 | 20 | 50 |

| Hydraulic power (kW) | 5.5 | 7.5 | 11 | 30 |

| Dimensions (L×W×H)(mm) | 2510×2060×2100 | 2660×2360×2100 | 2810×2750×2350 | 3210×3210×2680 |

| Overall weight (kg) | Approx 1300 | Approx 1600 | Approx 2100 | Approx 3500 |

The above models are standard universal models. If you require other models, please contact our staff, and we can also provide customized services according to your needs.

1. Simple operation

Three-step boot-up, intelligent PLC program control design by engineers to ensure optimal operation of the equipment.

2. Easy bagging

Designed with ergonomic principles, making bagging operations easy and reducing fatigue.

3. Adjustable parameters

Easy switching between single-time/continuous operation; freely adjusting between press-loose/press-tight settings.

The hydraulic bagging baling machine realizes efficient compression and standardized packaging of loose materials through intelligent hydraulic system and modular design. Its technical process can be divided into four key stages:

1. Multi-directional compression stage

Three-dimensional pre-compression system

The main hydraulic cylinder (pressure range 20-50MPa) drives the pressure head to perform multi-directional cyclic compression in the compression chamber (usually 3-5 times), and by alternating the direction of force application, the loose materials such as wood chips and fibers can reach a uniform density (300-800kg/m³ adjustable).

Intelligent pressure control

The PLC system monitors the oil pressure and displacement sensor data in real time, dynamically adjusts the number of compressions and the holding time (5-30 seconds), and ensures that materials with different moisture contents (15%-45%) can form stable blocks.

2. Forming and bagging stage

Rectangular mold forming

The compressed material is pushed into the standard rectangular outlet mold (common size 600×400×300mm). The modular design supports rapid mold replacement to meet different specifications.

Automatic bagging device

The photoelectric sensor triggers the automatic bagging mechanism of the PE bag (optional vacuum exhaust interface), and cooperates with the heat sealing device to complete the bag sealing. The moisture-proof level can reach IP65 (when combined with vacuum packaging).

3. Integrated control

Precise metering system

When working in conjunction with the weighing conveyor, the weight of each package is controlled by a high-precision load cell (error ±0.5kg), and the preset value lock within the range of 25-1000kg is supported.

Production line collaboration

When forming an intelligent production line with a crusher and a screening machine, speed synchronization is achieved through an industrial bus (such as PROFINET), and the processing capacity can reach 5-20 tons/hour.

4. Special application design

Moisture-proof and anti-corrosion solution

Use multi-layer composite PE bags (thickness 0.15-0.3mm optional) + vacuum pump group (optional) to make the internal humidity of the package ≤10%, suitable for humid environments such as sea transportation.

Safety and stability features

Equipped with an overload protection valve and an emergency return button, it automatically releases pressure when overloaded by 160%, and the equipment noise is controlled below 75dB(A) (with a soundproof cover).