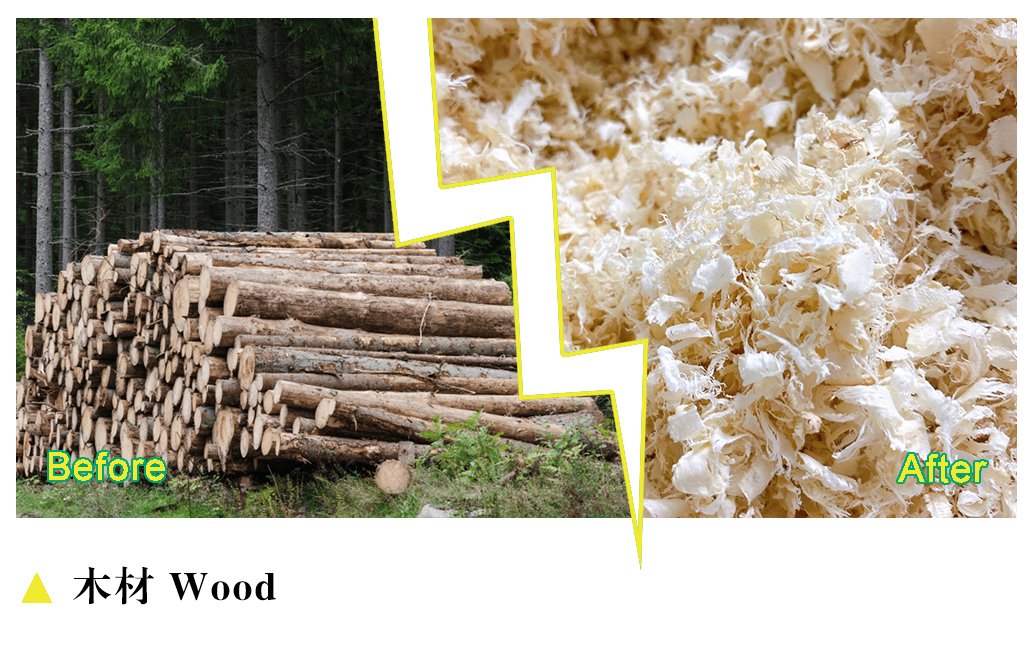

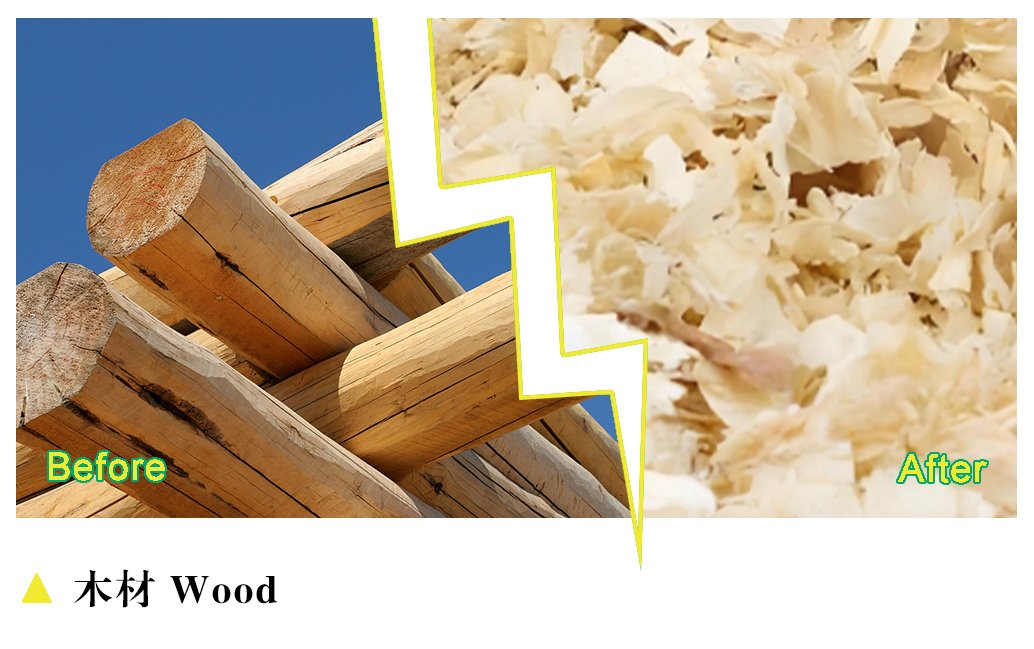

The high-linear-speed blades of the wood shavings machine rapidly plane wood to produce thin wood flakes. As the wood in the flaker box moves reciprocally relative to the cutter shaft through chain-driven mechanism, the blades continuously plane all surfaces of the material, generating consistent wood flakes that are discharged via the under-mounted conveyor.

The main motor of the wood shaving machine directly drives the knife shaft to rotate through the V-belt, and the high-speed blade quickly shaves the wood to produce thin wood shavings. The planing box motor reducer drives the planing box to reciprocate through the sprocket chain, and the wood in the planing box also reciprocates with the planing box relative to the knife shaft. In this process, the blade continuously shaves various positions of the wood, and wood shavings are continuously produced. The produced shavings are then conveyed out through the conveyor belt below.

| Animal Breeding | Producing bedding materials for pets such as hamsters and laboratory animals like mice, producing absorbent and insulating materials for farms such as for chickens, horses, and rabbits. |

| Packaging Materials | Producing wood shavings used as fillers for protecting fragile items during packaging. |

| Paper Industry | Producing fine wood shavings used as pulp material in the papermaking process. |

| Flower Breeding | Producing fine wood shavings used as organic fertilizer in horticulture. |

| Bioenergy | Producing fine wood shavings used as biomass fuel. |

| Furniture Manufacturing | Producing wood shavings used as raw material for making chipboards, fiberboards, and other types of boards. |

| Model | GFW-C106 | GFW-C109 | GFW-C306 |

| Planer box dimensions(mm) | 1430×590 | 1430×890 | 2130×590 |

| Swing diameter(mm) | φ160 | φ160 | φ300 |

| Roller length(mm) | 600 | 900 | 600 |

| Motor power(kW) | 7.5×4 | 11×4 | 11×4 |

| Dimensions(L×W×H)(mm) | 3780×1600×1500 | 3780×2000×1500 | 4880×1850×2080 |

| Overall weight(kg) | Approx 2200 | Approx 2500 | Approx 5000 |

The above models are standard universal models. If you require other models, please contact our staff, and we can also provide customized services according to your needs.

1. Strong adaptability

Can adjust the thickness of the wood chips and change the size of the chips according to needs.

2. High economy

Blades are highly hard and wear-resistant, and can be reused multiple times by grinding or changing angles.

3. Ease of operation

High degree of automation, simple and easy to operate.

The wood shavings machine (also known as wood chipper or wood flaker) is designed for wood processing, biomass energy and renewable resources industries, and has become an industry benchmark with its excellent cutting efficiency and stable performance.

Efficient cutting, flexible customization

High production capacity, stable operation

Industrial-grade durable design

Feeding system

Cutting and crushing unit

Grading and screening system

Power transmission system

Intelligent control system