Basic Company Information

KUNSHAN BOJIN TRADING CO.,LTD.

KUNSHAN BOJIN TRADING CO.,LTD.

TEL : 86-512-57169166 / FAX : --

11th Floor, JingZuan Building, No 875,XIAOLIN ROAD,KUNSHAN CITY,JIANGSU P.R.C 215316 Jiangsu Kunshan China [CN]

Homepage : http://www.bojin.hk/

Main Products

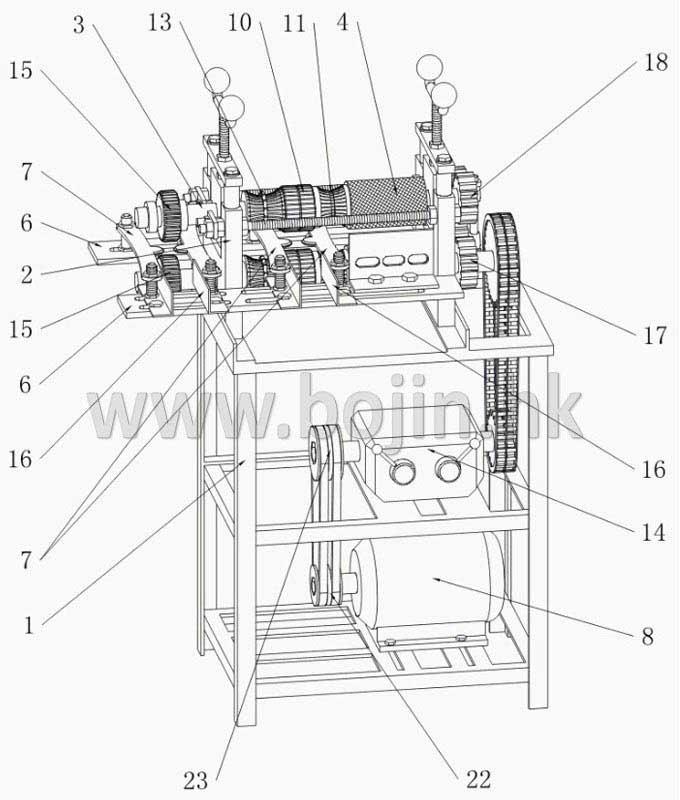

Automatic tape dispe , Wire Stripping Machi , , ,

Company Advantage

BOJIN is a leading Manufacturer and Exporter of The Newest High Quality Small Automatic Machines. Its main products include Wire stripping machine, automatic tape dispenser , label dispenser, label rewinder, labeling machine, tape cutting machine, wire winding machine, terminal crimping machine, twist tie machine, harness taping machine etc.

Detail Company Introduction

BOJIN is a leading Manufacturer and Exporter of The Newest High Quality Small Automatic Machines. Its main products include Wire stripping machine, automatic tape dispenser , label dispenser, label rewinder, labeling machine, tape cutting machine, wire winding machine, terminal crimping machine, twist tie machine, harness taping machine etc.

Factory Information

Factory Location

Factory Address

11th Floor, JingZuan Building, No 875,XIAOLIN ROAD,KUNSHAN CITY,JIANGSU P.R.C 215316

Factory Size

5,000-10,000 square meters , 21-30 People

No. of R & D Staff

21-30 People

No. of Production Lines

5

Annual Output Value

US $10 Million - US $50 Million

Trade Information

Total Annual Sales Volume

US $2.5 Million - US $5 Million

Export Percentage

21% - 30%

Accepted Delivery Terms

FOB , CFR , DEQ , DDP

Accepted Payment Currency

USD , EUR

Accepted Payment Type

T/T , L/C