Specification for

With its small footprint and combination of precision cutting and fast printing into one compact device, the CJV30-160 is ideal for sign makers and other print services who offer over the counter services. Despite the combining of two efficient machines into one, the CJV30 series is very user friendly and offers the unique features of continuous unattended printing and cutting from start to finish, which allows for high productivity. The integrated pre-point heating system for enhanced color development and ink fixing, as well as the reliable media feeding system and take up device, allows for consistent and quality products.

The CJV30-160 comes with high performance RIP software, with the newest 16-bit rendering capability included. Mimaki CJV30-160 is for print service providers engaged in printing of large sized signage and vehicle markings

Easy Production of Seals, Labels and Stickers.・Max. Print / Cut Width:610mm(24.0")・Media Width:100(3.93")~620(24.4")mm・Sticker / Labels, Pop, posters

Fast Generation of A0 Size Posters and POP Displays.・Max. Print / Cut Width:1,020mm (40.2")・Media Width:100(3.93")~1,030(40.6")mm・Sticker / Labels, Pop, posters

Print Service Providers Engaged in Printing of Large Size Signage and Vehicle Markings.・Max. Print / Cut Width:1,361mm (53.6")・Media Width:100(3.93")~1,371(54.0")mm・Outdoor signs, Vehicle Graphics

Print Service Providers Engaged in Printing of Large Size Signage and Vehicle Markings.・Max. Print / Cut Width:1,610mm (63.4")・Media Width:100(3.93")~1,620(63.8")mm・Outdoor signs, Vehicle Graphics

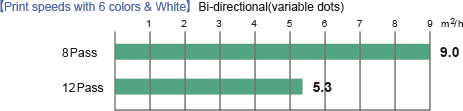

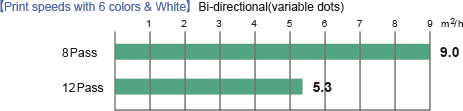

High speed printing at a maximum speed of 17.5 m²/h (540×720 dpi, 4 colors) and in standard mode at 11.9 m²/h (540×1,080 dpi, 4 colors).

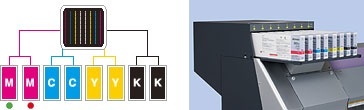

The symmetrical ink cartridge arrangement enables reliable and detailed high quality image generation even with bidirectional printing.

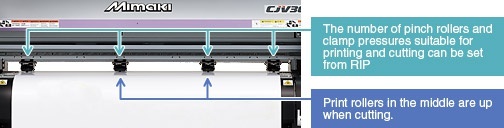

The number of pinch rollers and their clamp pressures can be set from RIP software and pinch roller pressures automatically changed according to media. By raising the intermediate pinch rollers on both sides at the time of cutting, media peel-off after cutting is eliminated.Enables unattended operation without manual intervention from start of printing to finished cutting.CJV30 automatically adjusts to ensure accurate media feed. This results in high quality finishing of both, print and cut.

When the ink cartridge runs out, another cartridge automatically begins to supply ink.Ink cartridges can be replaced during printing and overnight continuous printing is possible.*UISS only works in 4 color mode.

Highest resolution print output at 1,440 dpi with three different dot sizes.Generation of smooth and beautiful images without graining, even when printing in four color mode.

A photo-sensor on the cutting head automatically reads the registration marks on the print to precisely position the cutter automatically. Even with a laminated print, contour cutting is performed with great accuracy.

By using the fast drying SS21 solvent ink, the media can be cut directly after printing.Of course, the ink will not peel off during the cutting process.

Eco-solvent ink can be used safely in general office environments and does not require special ventilation equipment.

Mimaki's unique "White Ink Overlay Print" enables simultaneous printing of colors and white ink.When printing on transparent substrates, white ink underprinting enables printing of more vivid images.

Shining silver color gives your prints a metallic appearance.In combination with standard full colors,gold and bronze and other metallic effects can be printed.*For ES3 ink only

From RIP to cutting, Mimaki's software answers all professional requirements for multiple applications.In addition, easy to operate software for preparing the print & cut data is included.

Cutting data prepared in Illustrator (FineCut) can be combined with the associated printing data. Afterwards the CJV-30 starts consecutive print and cut operations.16-bit rendering tone jumps, white overlay printing and among other functions help to produce higher image quality.The web update function is added to easily achieve both software update and profile download.

Highly sophisticated requirements such as contour cutting are enabled. Furthermore tiling/nesting as well as large products can be accommodated.By incorporating RasterLink, print and cut can be easily operated from FineCut.

No previous experience of Illustrator is required for generation of vivid and creative stickers.Cut lines for the printed image are automatically generated by using the graphics and photo data. The software includes functions such as gradation settings etc.