Discharge fineness: <8 mm

Feed size.: <80 mm

Output: 40-70 T/H

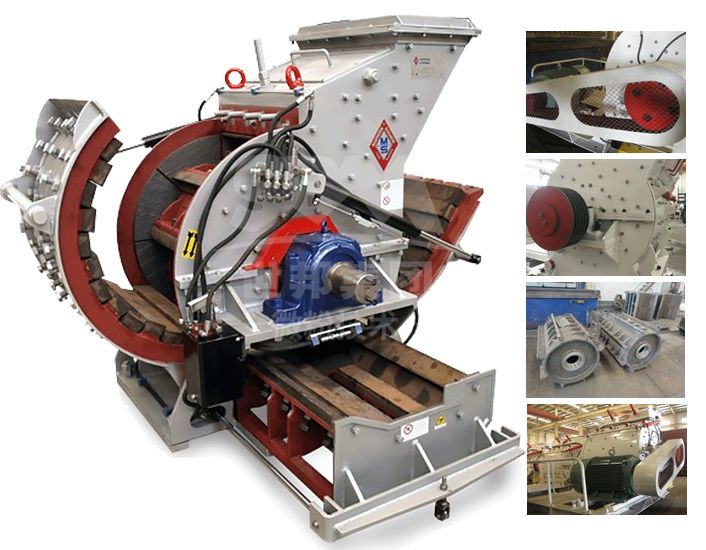

Coarse Powder Grinding Mill is engaging in crushing various rocks and stones with comprehensive strength not higher than 320 MPA into coarse powder and small particles.

It is widely used in metallurgy, mining, chemical, cement, coal, sand-making, construction, refractory materials, and ceramic industries.

Range of application: Barite, quartz, feldspar, mica, calcite, talc, apatite, gypsum, fluorite, limestone, dolomite, diatomite, ceramic soil, clay, marble, granite, fly ash, kaolin, calcium carbonate, slag, bauxite, glass, etc.

| Type | PC4008-75 | PC4012-90 | PC4015-132 |

| Rotor Diameter /mm | 750 | 900 | 1150 |

| Rotor Width/ mm | 800 | 1200 | 1500 |

| Rotor Speed/ r/min | 800-1000 | 800-1000 | 550-800 |

| Max Feeding Size/mm | <50 | <60 | <80 |

| Finished particle size /mm | 0-3 | 0-3 | 0-8 |

| Capacity / t/h | 10-30 | 30-60 | 50-100 |

| Power /kw | 55-75 | 75-90 | 45 |

| Hammer Number /pieces | 18 | 32 | 32 |

| Dimension L*W*H/mm | 2310*1665*1610 | 2840*2100*2020 | 3720*2650*2540 |