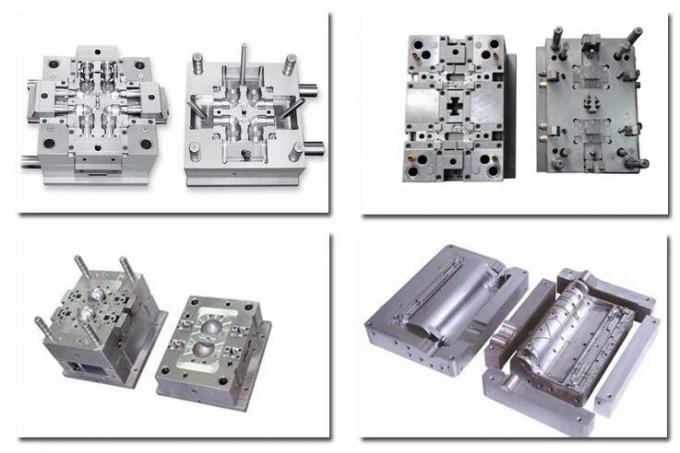

500000 Shots P20 ABS PP FUTA Plastic Injection Mould

Mold details description

| Plastic materials | PS, ABS, PP, PVC, PMMA, PBT, PC, POM, PA66, PBT+GF30%,Rubber, Silicone rubber, LSR, aluminum, zinc...Metal...etc. |

| Quality | ROSH and SGS standard |

| Size | According to your drawing |

| Mould Base | S50C HASCO standard, European standard, World standard |

| Mould Base Material | LKM, FUTA, HASCO, DME, etc. or as per customer’s requirement. |

| Surface Finishing | Texture (MT standard), high gloss polishing |

| Cavity / Core material | P20, 2311, H13, 2344, Starvax 420, 236,AdC3, S136, 2312, 2379, 2316, 2083, Nak80, 2767 etc. |

| Cavity Number | Single cavity, Muti Cavity, based on customer’s requirement. |

| Hot / Cold Runner | HUSKY, INCOE, YUDO, HASCO, DME, MoldMaster, Masterflow, Mastip,etc. |

| Mould Life | 1,000 to 1,000,000 shots(according to your requirement) |

| Design & Program Softwares | CAD, CAM, CAE, Pro-E, Solid works…etc. |

| Package | Standard Artificial Wooden Box with Steel Frame |

| Mold building lead time | 30~50 days after mold 3D approved, parts measurement report (upon required). |

| Annual production | 300-400 sets of mold |

Machine List

| Equipment | Model | Qty | Made in |

| CNC Center | YCM FV85A | 2 | Taiwan |

| Harford CNC-2150H | 2 | China | |

| OKUMA | 1 | Japan | |

| EDM Machine | ARD M30E | 7 | Taiwan |

| Sodick am30l | 3 | Japan | |

| AM30L | 1 | China | |

| Wire EDM | Charmilles 240 | 2 | Switzerland |

| GA64S | 1 | Taiwan | |

| Grinder | JL-614 | 3 | Taiwan |

| WP-614 | 5 | Taiwan | |

| Miller | Topone 3-5# | 5 | Taiwan |

| Die Spotting machine | NICE NC70-1007 | 1 | China |

| Die Rolling Machine | NICE NCF-5 | 1 | China |

| CMM | Mitutoyo C707 | 1 | Japan |

| Linear Height | TESA Micro-Hite M600 | 1 | Switzerland |

| Tool Microscope | Mitutoyo MF-A1720 | 5 | Japan |

| Projector | CPJ-3015Z | 1 | Taiwan |

| Gear Tester | OSAKA GTR-4LS | 1 | Japan |

KYE Mould was founded in 2009 in Chang`an Dong Guan, which is the high quality plastic mold and molding product center.Our enginer has 10-15 years experience of plastic mold and moding, with their professional they know how to help customer to save cost by offering high quality plastic mold and product.Usually, our price is 30% lower than Europe molds factory but with same quality.

We always keep perfect quality,best service and customer-first as our company-running theory as a result of winning big international market covering USA,Germany,UK,Italy,Australia,Middle-east ,South–east Asia and North Africa etc.

OUR ADVANTAGE

RAQ

Q1: Are you a factory or trading company?

A: We are factory in Chang`an, Dongguan, Guangdong ,China.We have our owned mold workshop around 2000 square meters including mold and molding.

Q2: What kind of service do you provide?

A: We can offer mould making, die casting, CNC machining, stamping, Plastics injection moulding, assembly and various metal surface treatment.

Q3: How long should we take for a project inquiry?

A: After receiving detail information we will quote within 2 days.

Q3: What is the software you use for design and mold making?

A: We usually use UG, PROE, CAD, CAD/ProE/UG/SOLIDWORKS for mold 2D and 3D design.

Q4: Will offer the free sample?

A: We offer 10-20pcs free sample for each mold trial and the customer could in charge of sample delivery cost.

Q5: What is your payment term and how do you pack the mold for delivery?

A: Usually, our payment term is 50% on PO, 30% on T1 sample and 20% on mold approval before delivery by T/T.