1.Equipped with exhaust device, have good exhausting effect and little pollution.

2.Small occupied area, high system integration, convenient to operate and maintenance,24 hours continuous working.

3.The water chiller has good safety protection function, such as over temperature, lack phase, pressure, water-break, undervoltage, overload, etc. With stable performance, satisfied the cooling requirement of laser source.

Specifications:

|

Model |

GS-LFD3015 |

|

Laser source medium |

Fiber |

|

Laser power |

500W~1500W |

|

Cutting range(L*W) |

3000mm × 1500mm |

|

Z axle stroke |

100 mm |

|

Max cutting speed |

36m/min |

|

Max positioning speed |

120m/min |

|

Wok platform size/Max height of feeding material |

4250x2500mm/more than 120mm |

|

Cooling form |

water cooling |

|

Laser wavelength |

1070nm |

|

Min. cutting gap |

≤0.1mm |

|

Positioning accuracy of X, Y and Z axles |

±0.03 mm |

|

Repeated positioning accuracy of X, Y and Z axles |

±0.01 mm |

|

Thickness of cutting material(according to material) |

0.2-14mm |

|

Drive model |

Imported servo motor |

|

Power requirement |

380V,50/60Hz |

|

Working temperature |

5℃-45℃ |

|

Continuous working time |

24 Hours |

|

Machine weight |

About 6750Kgs |

|

Outer dimension |

4270mm x2280mm x 1750mm |

|

Total protection level of power supply |

IP54 |

Japanese Fuji Servo Motor of strong rigidity, excellent control ability, accurate, sensitive response

1 Outstanding performance with the highest level of response of amplifier in the industry, the setting time is shortened in a high degree.

2 Enhancement of the Vibration suppression function to improve the track ability and decrease the setting time. Reduce the vibration when driving and reduce the fore-end vibration when stop working

3 Easy start up: simple installation and setting. The connection can be finished one time with Sigma Win+Connection confirmation function.

4 Standard configuration with analog quantity, instruction form of pulse sequence type and MECHATROLINK-II com

Features:1.12mm Steel frame,more firmly2. Famous system, Beckhoff CNC Control System8. Cooling system,water cooling and air cooling4. Removable control cabinet,maintenance more convenient5. Control cabinet air condition,more secure,more intimate6. Double dedusting system,more environmentally friendly and safe.7. Double drive system,YASKAWA,helical gear drive.Drive faster,more stable8. Safety protection of cutting head,focal length adjustment,drawer type protective lens9. Gantry beam,cast aluminum.High performance,no deformation,light weight and working fast10. Lubrication system,manual one key lubrication and computer control automatic lubrication11. Material protection feeding system,three sides pulley feeding and hydraulic pressure push rod feeding

Key parts of our machine are original imported world famous brand with good quality

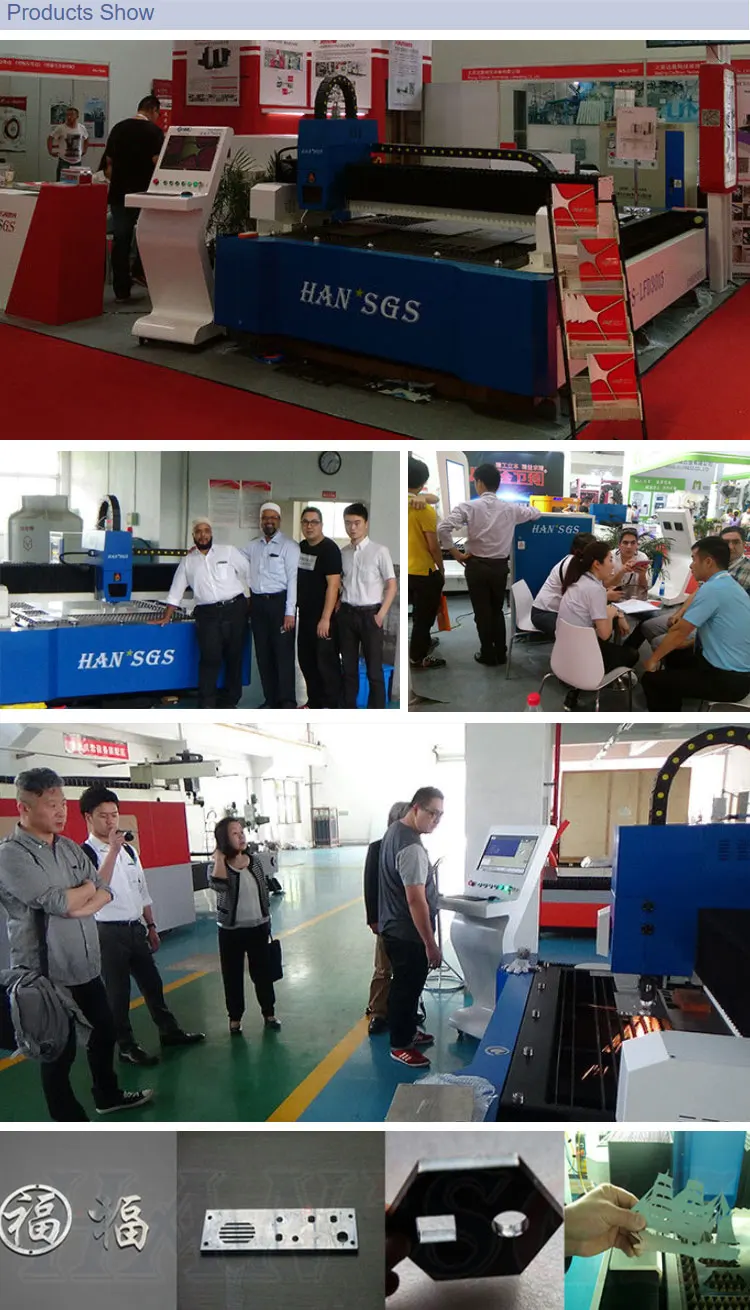

Applications

Metal processing, sheet metal industry, automobile industry, military industry, aerospace, pressure vessel manufacturing, metallurgy, steel rolling, oil pipe, machinery manufacturing, household appliances industry, advertising industry, lighting industry, etc.

Sample

Technical Support

Guided with our company culture of “Grape market with service" and with the service idea for getting users’satisfaction as well as

customer’s profit, our company set up special technical team for laser cutting, welding, heat treatment cladding, perforating

appliance with strategic agreement signed with IPG USA, LASERLINEDILAS Germany, ABB Robot Switzerland, KUKA Robot

Switzerland, Material Colleague of Tsinghua University, aviation material institution, material colleague of Wuhan university of

science and technology to provide long term technical support for our users.

We will provide comprehensive technical support for customer and our technique process database.

1) Specified technical train and instruction to ensure master of operation.

2) Process and technical instruction for typical work piece to master the basic selection of parameter for the laser processing.

3) Comprehensive technique support for new technique development by customer.

5) Technique live service.